Our Services

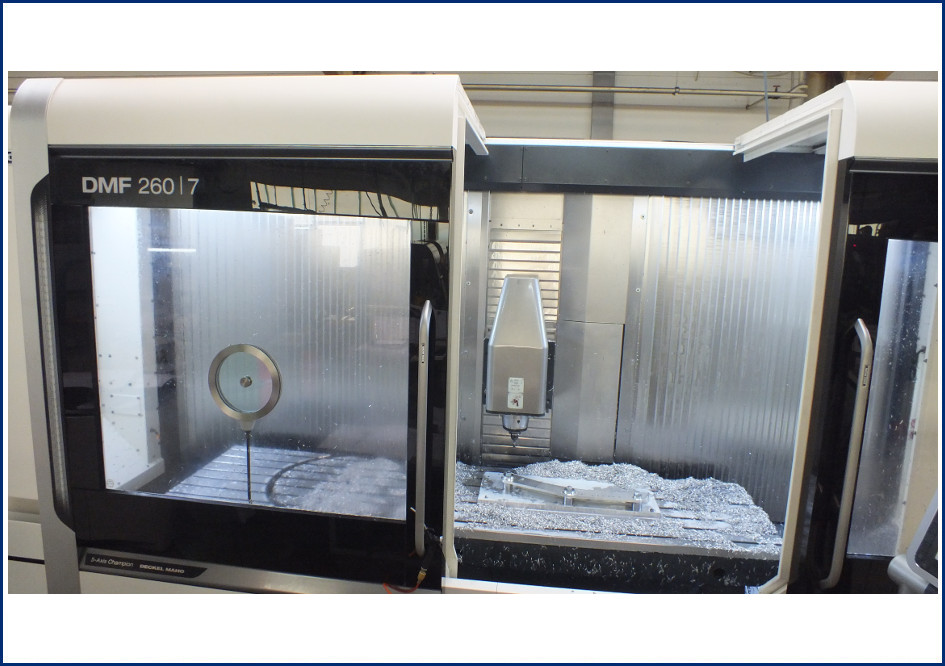

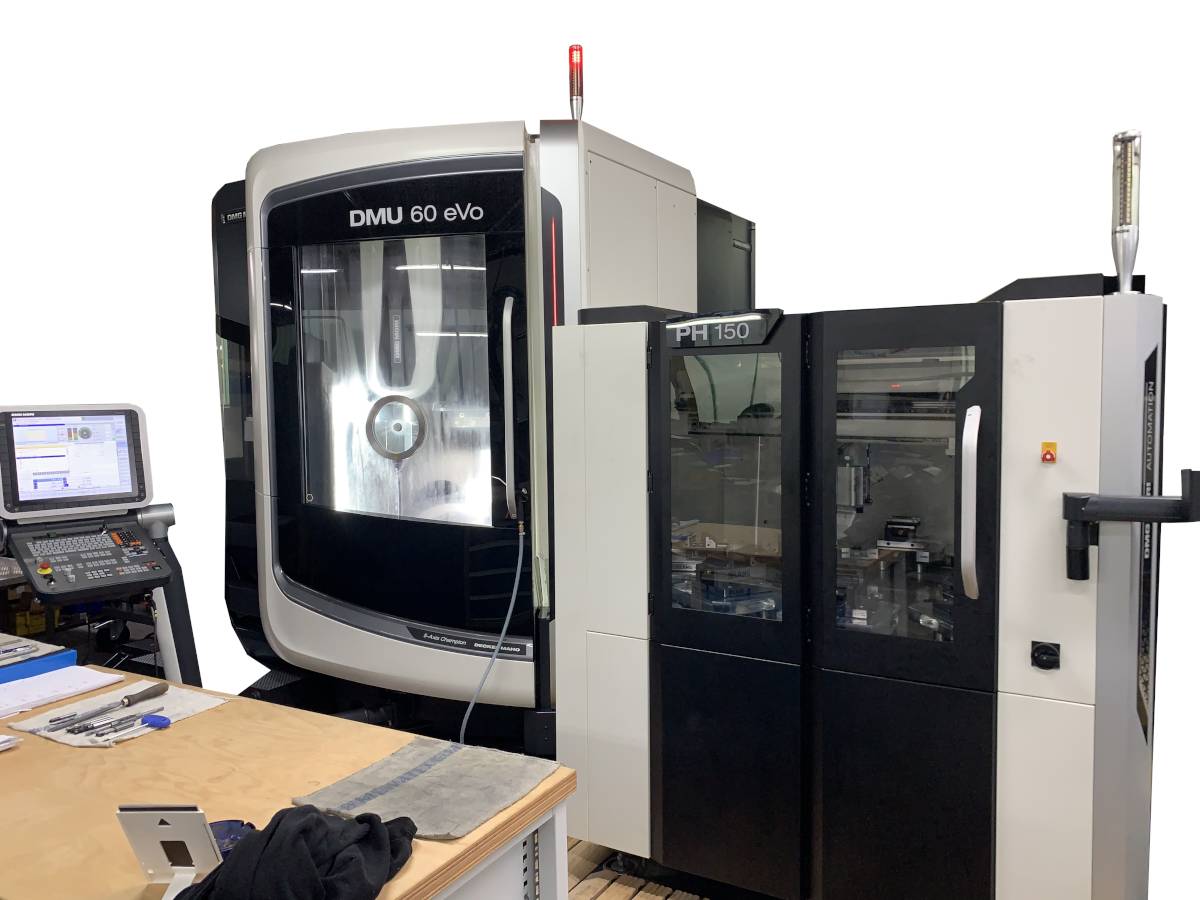

Milling

On our modern CNC machining centers, we manufacture simple and complex individual parts from single parts to small series. If you provide us with a 3D model, the CNC programs are created via a CAM system.

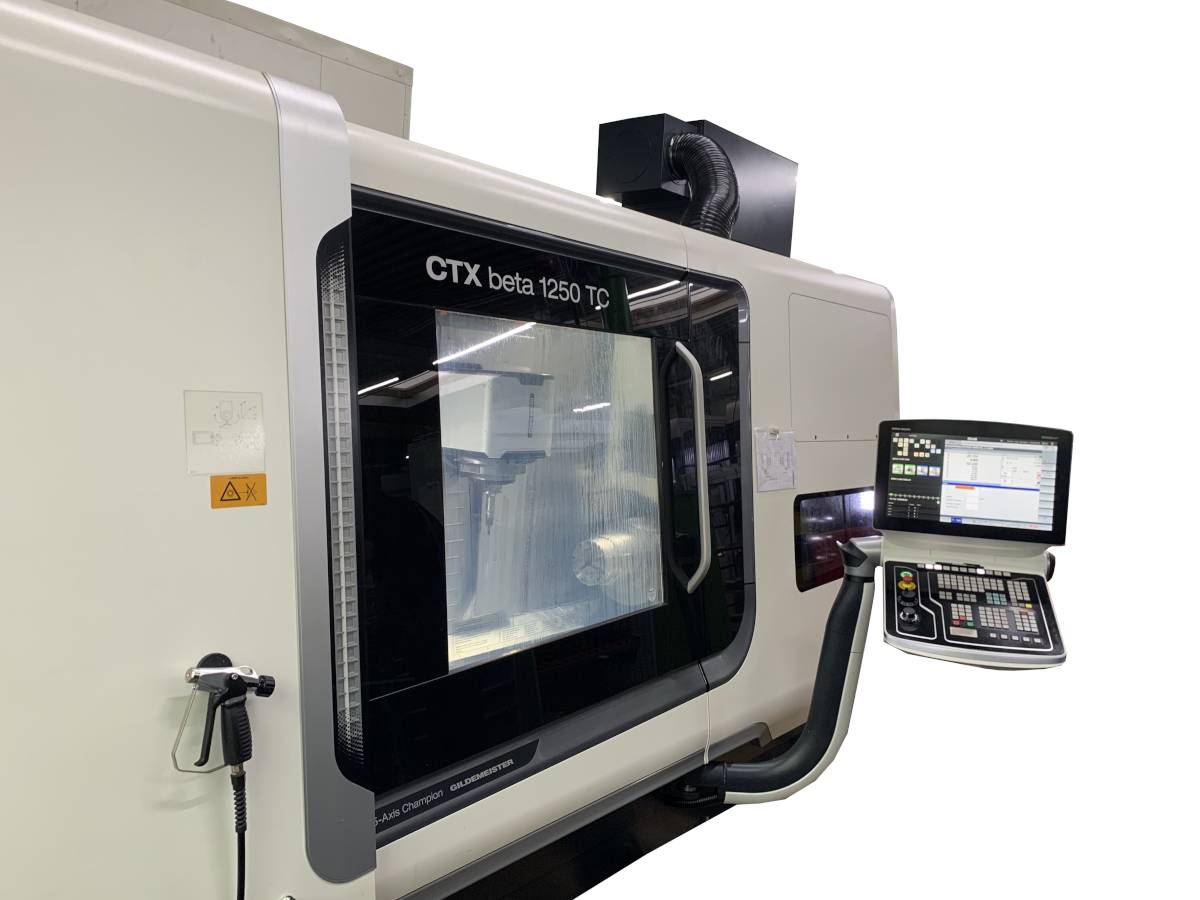

Turning

We manufacture simple and complex individual parts, as well as turned and milled parts, which range from single components to small batches, on our state-of-the-art CNC lathes. If you provide us with a 3D model, the CNC programs will be created via a CAM system.

Turning - Milling - Grinding

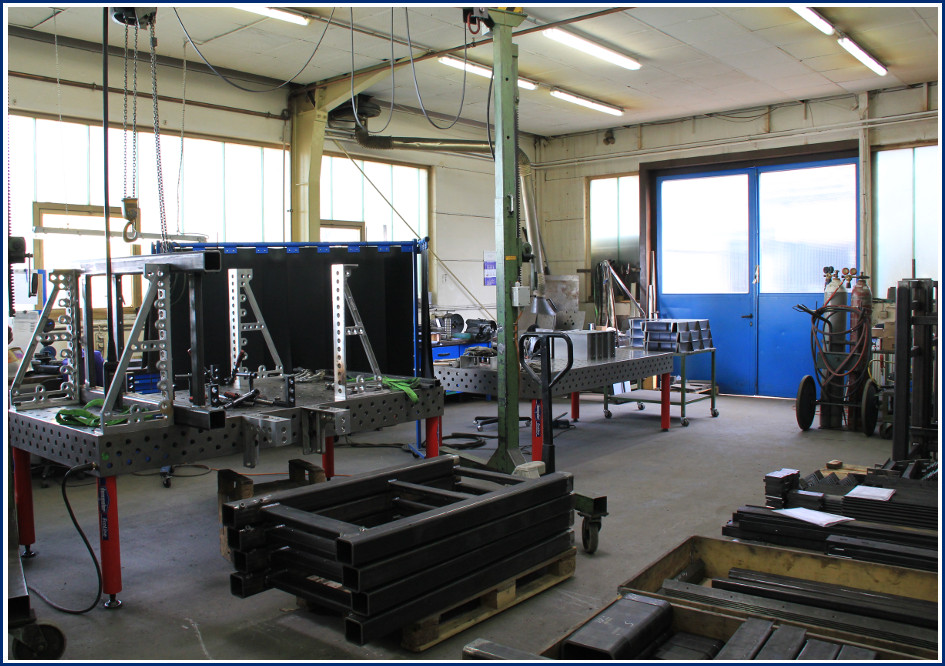

Welding

We’ve been a DIN-certified specialist welding company (DIN 11800-7 class D - advanced certificate) since 2004. In 2013 we extended our certification to DIN 18800-7 class E and introduced qualification for EN-1090-1 EXC 3.